Principle of injection molding process

Injection molding is a manufacturing process widely used in the production of various plastic products. The principle of injection molding is based on a series of precise and controlled steps.

Firstly, plastic pellets or granules are fed into a heated barrel. Here, they are melted by the application of heat and the mechanical action of a screw or plunger. The molten plastic is then forced under high pressure into a mold cavity.

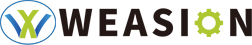

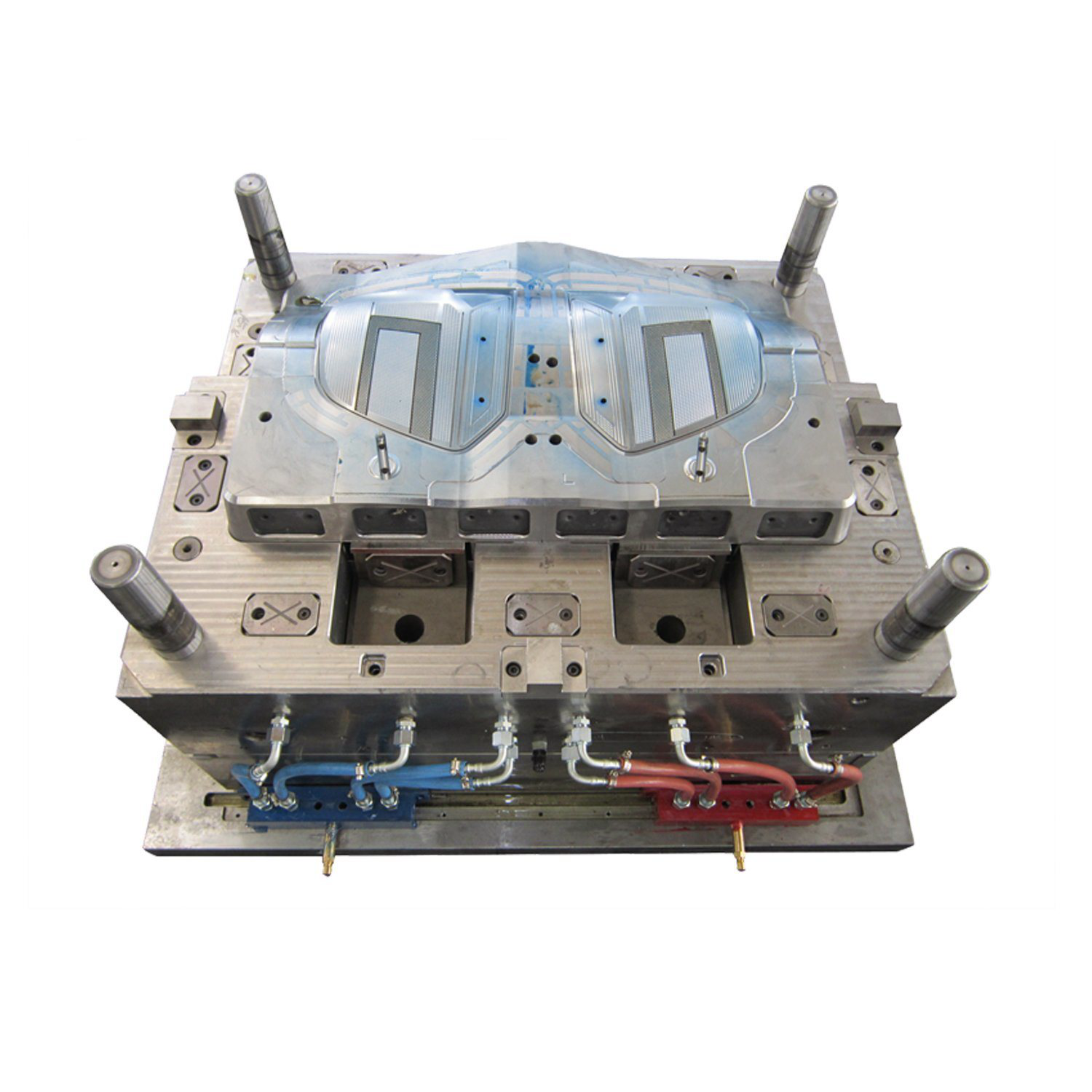

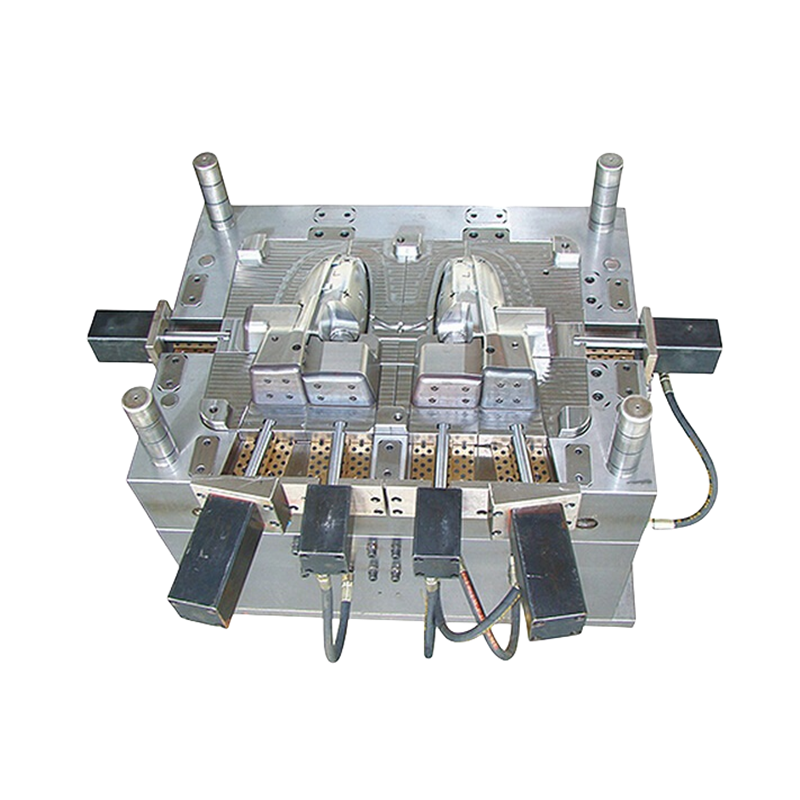

The mold cavity is designed to have the exact shape and dimensions of the desired final product. As the molten plastic fills the cavity, it takes on the form of the mold.

After the mold is filled, the plastic is allowed to cool and solidify. Once solidified, the mold is opened, and the finished part is ejected.

This process is highly repeatable, allowing for the mass production of identical plastic components with high accuracy and consistency in quality. The key factors influencing the quality of the final product include the temperature, pressure, injection speed, and cooling time, all of which need to be precisely controlled and optimized for each specific molding operation.

In summary, injection molding works by melting plastic, injecting it into a mold at high pressure, cooling it to form the desired shape, and then extracting the finished product.